Newsroom

Affordable Metal Hydroxide Catalyst Enhances Oxygen Production for Clean Energy

A groundbreaking catalyst made from abundant and inexpensive components redefines efficiency in oxygen evolution reactions, paving the way for affordable and scalable hydrogen fuel production.

Innovating Catalyst Design with Metal Hydroxide-Organic Frameworks

An electrochemical reaction that splits water molecules to produce oxygen underpins several approaches to generate alternative chemical fuels for transportation. This reaction depends on catalysts, which currently require rare elements like iridium, restricting fuel production potential. Researchers at MIT and collaborators have developed a novel catalyst type—metal hydroxide-organic frameworks (MHOFs)—constructed from inexpensive and abundant components. This new family of materials allows precise tuning of structure and composition to meet specific chemical process needs, matching or outperforming traditional expensive catalysts.

Applications and Impact of Oxygen Evolution Reactions

Oxygen evolution reactions are crucial in electrochemical fuel, chemical, and material production processes. These include hydrogen generation as a byproduct—which serves as a clean fuel or precursor to other transportation fuels—ammonia manufacturing for fertilizers or chemical feedstocks, and carbon dioxide reduction for emission control. Without catalysts, these reactions proceed sluggishly, requiring extra energy that reduces overall efficiency. By lowering the energy input needed, catalysts enable faster and more efficient reactions.

“This family of materials really offers a new space to tune the active sites for catalyzing water splitting to produce hydrogen with reduced energy input.”

Advancing Earth-Abundant Catalysts

Traditional catalysts rely heavily on scarce and costly metals like iridium oxide. The MIT team’s MHOFs provide a promising alternative using Earth-abundant elements such as nickel and iron, making the catalysts potentially over 100 times cheaper. Unlike previous metal hydroxides that were difficult to customize, these MHOFs leverage nanostructuring inspired by metal-organic frameworks (MOFs) to precisely control electronic properties and enhance stability for long-term use.

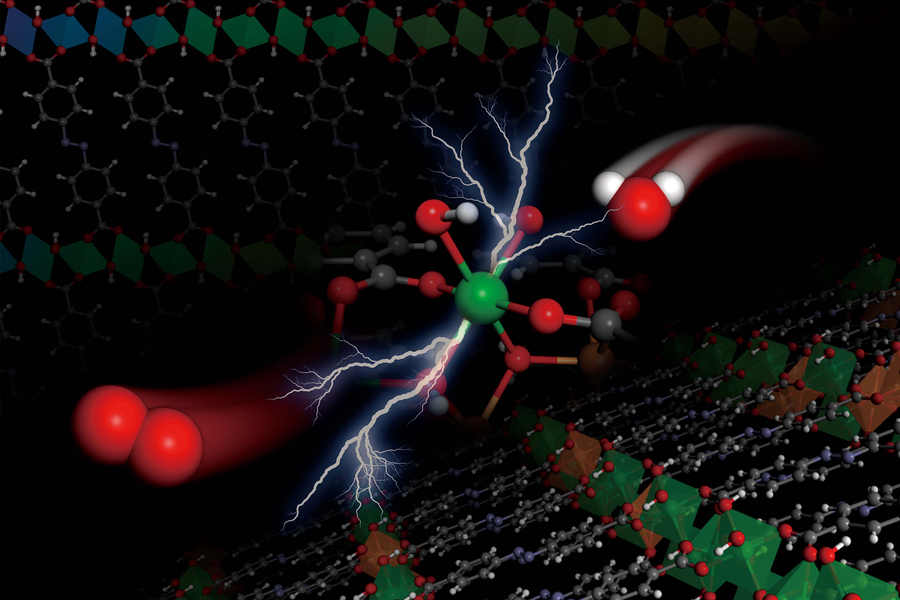

Illustration of MHOF nanostructured design enabling enhanced catalyst performance.

Future Directions and Scalability

The newly developed MHOF catalysts demonstrate five times greater tunability than existing nickel-based catalysts by substituting different metals in their composition. They can also be produced as extremely thin sheets, reducing costs further when coated onto other substrates. While current tests remain at laboratory scale, efforts are underway to scale production commercially within a few years.

Supported by the Toyota Research Institute and involving institutions such as Stockholm University and SLAC National Accelerator Laboratory, this research points toward a future where clean hydrogen fuel production is both affordable and scalable without reliance on precious metals.