Newsroom

Innovative Continuous Toxic Gas Detector Using MOF-Polymer Composite for Enhanced Sensitivity

Traditional gas detection systems are limited by short lifespans and single-use capabilities. MIT researchers have now developed an innovative, low-cost gas detector enabling continuous monitoring of toxic gases with enhanced sensitivity and durability.

Innovative Composite Materials for Gas Detection

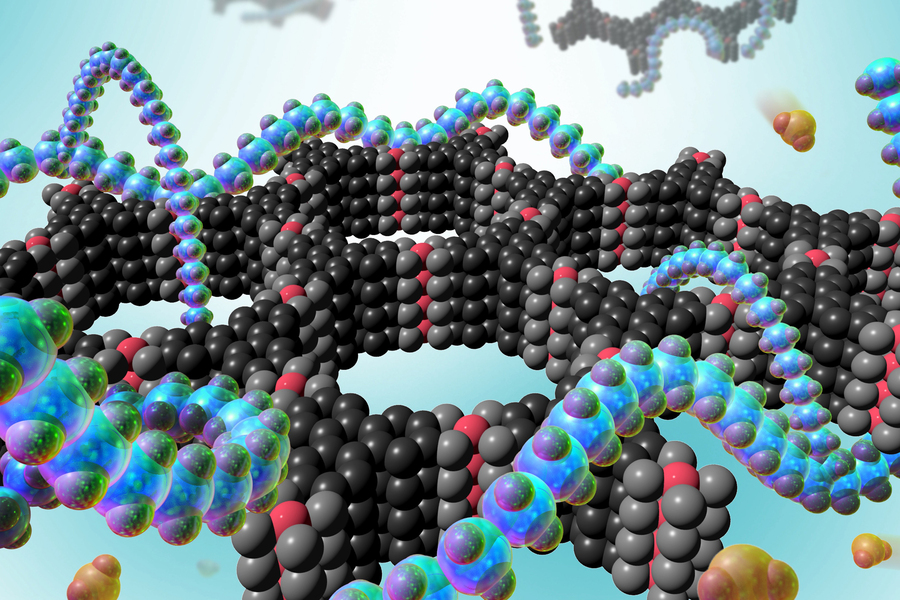

MIT’s new detection system ingeniously merges metal-organic frameworks (MOFs) with durable conductive polymers. MOFs, known for their porous structures and electrical conductivity, effectively trap gas molecules but saturate quickly. Combining them with reversible polymer composites overcomes this limitation, enabling repeated sensing cycles.

Exceptional Sensitivity and Reversibility

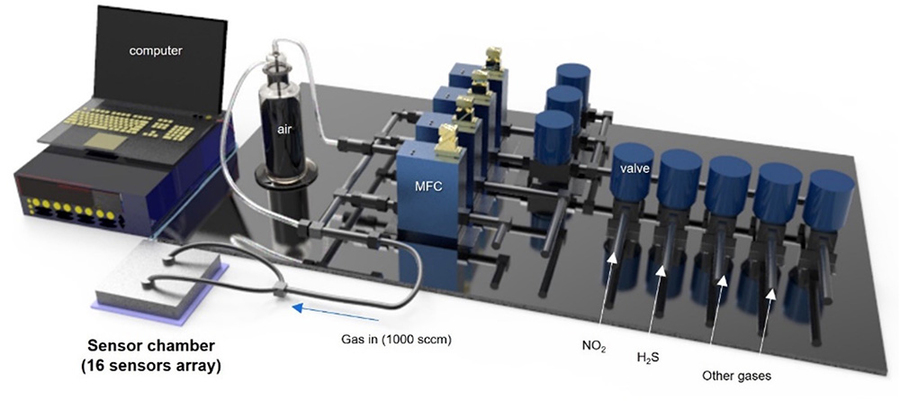

The composite sensor changes electrical resistance when gas molecules are temporarily absorbed, allowing continuous monitoring. Laboratory tests showed successful detection of nitrogen dioxide over 100 cycles with minimal baseline deviation, surpassing conventional detectors in sensitivity down to 2 ppm.

“This innovative sensor combines high sensitivity with excellent reversibility, enabling continuous toxic gas monitoring never before achievable in low-cost systems.”

Versatile Applications and Scalable Manufacturing

The thin polymer films enable easy integration into handheld devices and smoke alarms while minimizing production costs. Adaptable for various toxic gases, the sensor’s coating process aligns with standard industrial techniques, promising broad real-world deployment possibilities.

Future Directions and Environmental Impact

Future work will focus on real-world field tests such as chimney or exhaust pipe monitoring using integrated resistance devices to ensure selectivity amid complex contaminants. Supported by MIT Climate and Sustainability Consortium and the U.S. Department of Energy, this research offers promising advances in environmental safety and public health.