Newsroom

Innovative Ladder Polymer Membranes for Efficient Gas Separation and Emission Reduction

A revolutionary membrane technology developed by researchers from MIT and Stanford drastically reduces energy use and emissions in industrial chemical separations by overcoming the long-standing tradeoff between permeability and selectivity.

Innovative Hydrocarbon Ladder Polymers

Industrial chemical separations consume about 15% of the world’s energy and contribute significantly to greenhouse gas emissions. The newly developed membranes, based on hydrocarbon ladder polymers, provide unprecedented performance with both high permeability and selectivity, enabling a roughly tenfold reduction in energy use compared to traditional methods like distillation.

Breakthroughs in Polymer Chemistry and Structure

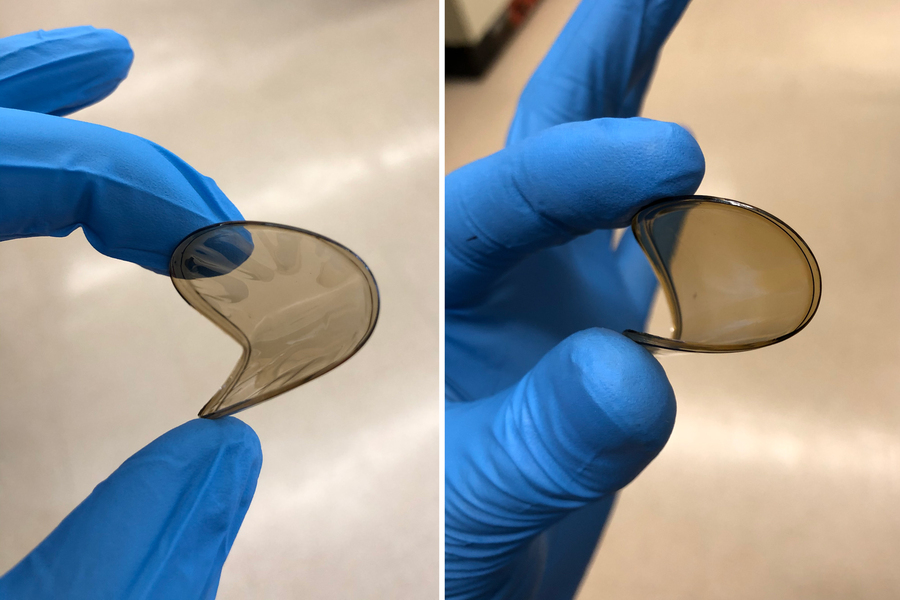

These ladder polymers are synthesized through an innovative chemistry called CANAL (catalytic arene-norbornene annulation), which forms rigid, kinked ribbon-like strands with tunable sub-nanometer pores. This unique structure offers mechanical robustness and improved selectivity for gases with similar molecular sizes, such as oxygen and nitrogen.

Superior Gas Separation Performance

The membranes exhibit remarkable results, including five times the selectivity and 100 times the permeability for carbon dioxide separation compared to existing cellulosic membranes. For hydrogen separation from methane, they are 100 times more permeable and three times as selective. This combination outperforms all known polymer materials in many applications.

“These new membrane materials have the highest combination of permeability and selectivity of all known polymeric materials for many applications.”

Industrial Potential and Environmental Impact

With their strength, ductility, and solubility in certain solvents, CANAL polymers could be scaled rapidly for industrial use. Applications include natural gas purification, carbon capture, biogas fuel refinement, and hydrogen production, all crucial for transitioning to a low-carbon economy.

Collaborative Research and Future Outlook

The collaboration between chemistry and membrane experts from Stanford, MIT, and King Abdullah University has propelled this technology forward. Supported by prestigious institutions and funded initiatives, the team is refining these membranes to facilitate industrial scale-up and maximize their role in decarbonization efforts worldwide.

Image credit: MIT and Stanford Research Team