Newsroom

Innovative Model Enhancing Lithium-Ion Battery Performance and Charging Speed

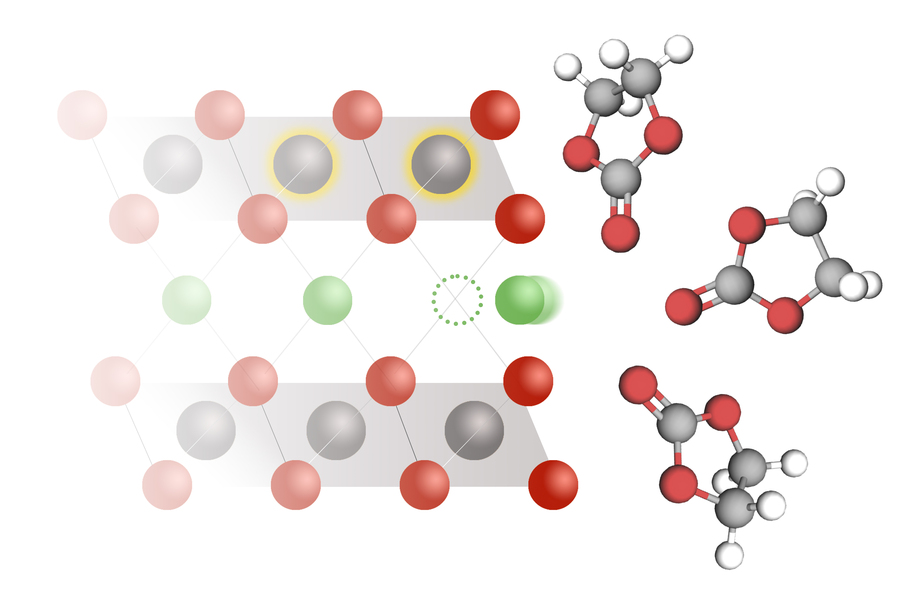

At the core of lithium-ion batteries lies a fundamental reaction: lithium ions, dissolved in an electrolyte solution, intercalate into a solid electrode during discharge. When these ions de-intercalate and return to the electrolyte, the battery recharges. This cycle occurs thousands of times over a battery’s lifespan, with its power generation capacity and charging speed depending on the efficiency of this reaction. However, the precise mechanisms behind this process and the factors influencing its rate have remained largely unexplored. In a groundbreaking study, researchers from MIT have measured lithium intercalation rates across various battery materials. Their findings led to the development of a new model that elucidates how this reaction is controlled. The model suggests that the intercalation process is influenced by a phenomenon called coupled ion-electron transfer, where an electron is transferred alongside a lithium ion to the electrode. The insights derived from this model could pave the way for the design of more powerful and faster-charging lithium-ion batteries. According to Martin Bazant, the Chevron Professor of Chemical Engineering at MIT, “Our goal is to enhance the speed and control of these reactions, thereby accelerating both charging and discharging processes.” Additionally, this new model may provide valuable understanding into why modifications to electrodes and electrolytes can lead to improved energy density, power output, and overall battery longevity—a process traditionally approached through trial and error. Yang Shao-Horn, the J.R. East Professor of Engineering at MIT, remarks, “This research unifies various observations regarding reaction rates across different materials and interfaces into a cohesive theory of coupled electron and ion transfer for intercalation, building upon earlier work on reaction kinetics.” The study’s lead authors include Yirui Zhang, now an assistant professor at Rice University; Dimitrios Fraggedakis at Princeton University; Tao Gao from the University of Utah; and MIT graduate student Shakul Pathak. The paper is published in the journal Science. For decades, scientists believed that the rate of lithium intercalation at an electrode was primarily determined by how quickly lithium ions could diffuse from the electrolyte into the electrode, following a model known as the Butler-Volmer equation. However, attempts to measure lithium intercalation rates often yielded inconsistent results that contradicted predictions made by this model. Reports from different research teams have shown variations by factors up to 1 billion. In this study, the MIT team employed an electrochemical technique that applies rapid voltage bursts to an electrode, measuring lithium intercalation rates for over 50 combinations of electrolytes and electrodes. Their findings revealed that the actual intercalation rates were significantly lower than previously reported and did not align with predictions from the traditional Butler-Volmer model. The researchers proposed an alternative theory explaining how lithium intercalation occurs at the electrode surface. This theory posits that for a lithium ion to enter an electrode, an electron from the electrolyte must be simultaneously transferred to the electrode. Bazant explains, “The key step is not merely lithium insertion but rather electron transfer that reduces the solid material accommodating lithium. Both processes occur concurrently, enhancing one another’s effectiveness.” This coupled-ion-electron transfer (CIET) lowers the energy barrier for intercalation, thereby increasing its likelihood. The mathematical framework of CIET enabled researchers to predict reaction rates that were validated against experimental data and significantly differed from those predicted by the Butler-Volmer model. Furthermore, the study demonstrated that intercalation rates could be fine-tuned by altering electrolyte compositions. For instance, changing specific anions can reduce the energy required for lithium and electron transfer, enhancing overall efficiency. “Optimizing intercalation kinetics through electrolyte modifications offers tremendous potential for improving reaction rates and refining electrode designs, leading to enhanced battery power and energy output,” Shao-Horn states. Shao-Horn’s lab and collaborators are currently utilizing automated experiments to explore thousands of different electrolytes, developing machine-learning models aimed at predicting electrolytes with superior functions. These findings could also aid researchers in creating batteries with faster charging capabilities by accelerating lithium intercalation reactions while minimizing side reactions that contribute to battery degradation as electrons detach from electrodes and dissolve in electrolytes. Bazant emphasizes that a theoretical framework is essential for rational design rather than relying solely on trial and error: “Understanding critical material parameters will help guide future innovations in battery technology.” This research received funding from Shell International Exploration and Production and the Toyota Research Institute through the D3BATT Center for Data-Driven Design of Rechargeable Batteries.