Home > Product > Resinous > Epoxy Resin >

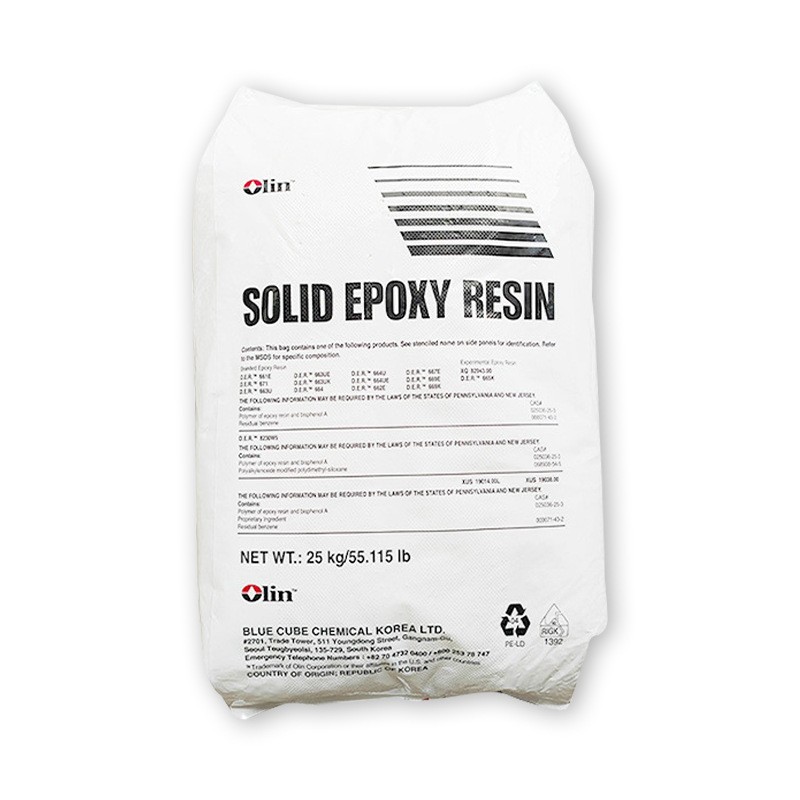

Olin Chemical Epoxy Resin D.E.R 664UE

Product Detail:

Olean Chemical Epoxy Resin D.E.R 664UE is a chemically modified medium molecular weight bisphenol A type solid epoxy resin, produced by the reaction of liquid epoxy resin with bisphenol A. CAS No. 61788 – 97 – 4.

Product Specifications:

- 25kg / package

Product Overview

Olean Chemical Epoxy Resin D.E.R 664UE is a chemically modified medium molecular weight bisphenol A type solid epoxy resin, produced by the reaction of liquid epoxy resin with bisphenol A. CAS No. 61788 – 97 – 4.

Product Characteristics

- Epoxy equivalent: epoxy equivalent of 860 – 930, higher epoxy equivalent in the curing reaction can form a more tightly crosslinked structure, which in turn affects the performance of the cured product.

- Viscosity: 25 ℃ when the viscosity of 5500 – 10200, moderate viscosity to facilitate the process of mixing with other substances, but also to ensure that in the coating or molding has a good leveling and operability.

- Flexibility: can significantly improve the flexibility of the cured product, so that the product has a certain degree of elasticity and bending resistance, can be used for higher flexibility requirements, such as some need to withstand dynamic stress or deformation of the parts.

- Adhesion: good adhesion to a variety of materials, can be firmly attached to the surface of metal, plastic, wood and other substrates to provide reliable bonding effect.

- Corrosion resistance: excellent corrosion resistance, can effectively resist the erosion of chemical substances, in harsh chemical environments can still maintain stable performance, suitable for applications that require resistance to acids, alkalis, solvents and other corrosive media.

- Thermal stability: with a certain degree of thermal stability, can maintain its physical and chemical properties within a certain temperature range, to meet some of the requirements of heat resistance application scenarios.

Product Applications

- Coating field: widely used in can coatings, coil coatings, powder coatings and so on. In can coatings, it can provide good inner coating protection to prevent corrosion caused by the contact between food and metal cans; in coil coatings, it can make the coating have good flexibility and weather resistance to adapt to the processing of coils and long-term outdoor use; in powder coatings, it can help to improve the fluidity and coating performance of the powder, and the cured coatings have good decorative properties and corrosion resistance.

- Other fields: It can also be used in some adhesives, electrical insulation materials, composite materials and other fields which have requirements for flexibility and corrosion resistance. For example, in adhesives, it can make the adhesive layer have better toughness and shear strength; in electrical insulating materials, it provides good insulating properties and environmental resistance; in composite materials, it enhances the bonding of matrix and fibers and other reinforcing materials, and improves the comprehensive performance of composite materials.