Newsroom

Revolutionary AI Technology Enhances Pharmaceutical Manufacturing Efficiency and Accuracy

In the pharmaceutical industry, isolating and drying active ingredients efficiently is crucial for producing pills and tablets that effectively alleviate ailments, yet traditional methods relying on human oversight introduce variability and inefficiencies.

Innovative Integration of Physics and Machine Learning

Recent research published in Nature Communications by teams from MIT and Takeda introduces the physics-enhanced autocorrelation-based estimator (PEACE), a method combining physics principles with machine learning to categorize particle surface roughness, aiming to improve pharmaceutical manufacturing efficiency and reduce failed batches.

Challenges in Traditional Monitoring Methods

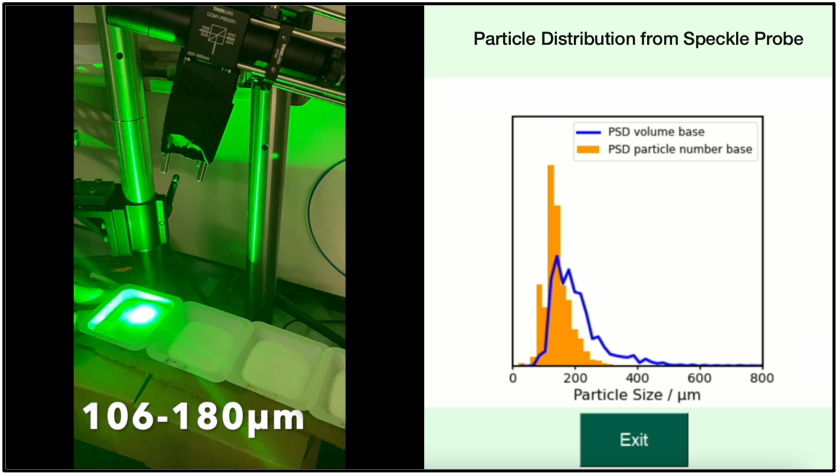

Conventionally, industrial dryers require halting to test samples off-line, introducing interruptions. Attempts to replace human operators with AI trained on video footage faced challenges due to subjective video selection, prompting a pivot to laser illumination techniques paired with physics-based analysis and machine learning for inline particle size measurement.

Efficiency and Safety Improvements

By analyzing laser interactions with materials using physics equations and minimal training data for machine learning, the PEACE method enables continuous monitoring without production stops, enhancing security and reducing handling of hazardous materials.

“This advancement represents a substantial leap forward in real-time monitoring of particle size distribution.” – Charles Papageorgiou, Takeda

Collaborative Future Prospects

The MIT-Takeda partnership has yielded multiple projects harnessing AI for healthcare innovation, with plans to expand laser-based monitoring to include camera analysis, accelerating industrial adoption through close lab collaboration and patent filings.