Newsroom

Revolutionary Sutureless Biopolymer Technology Enhancing Tissue Repair in Surgery

Revolutionary Sutureless Biopolymer Technology Enhancing Tissue Repair in Surgery

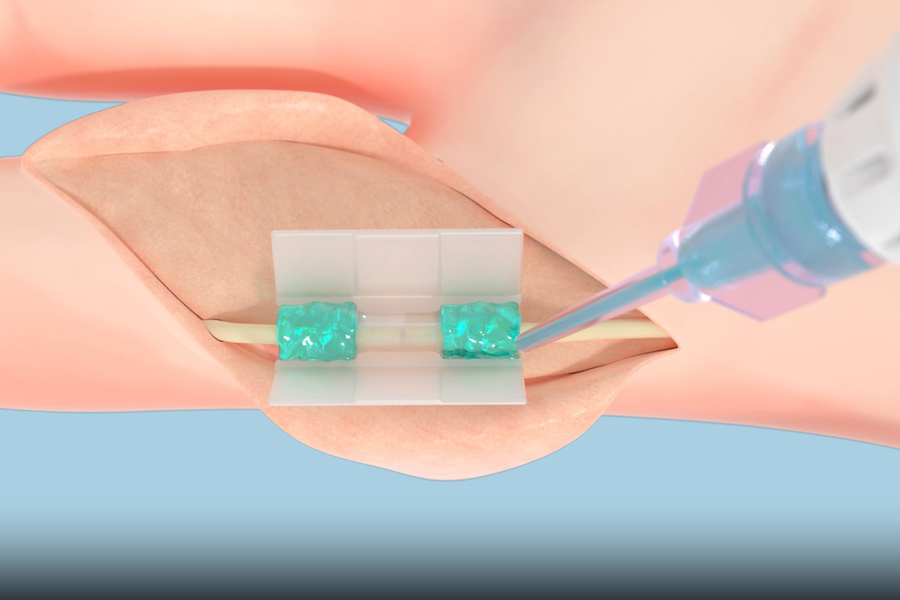

Surgeons traditionally rely on mechanical solutions such as sutures and staples for tissue repair, which can sometimes lead to additional damage. Other methods like meshes and glues may not bond effectively with tissues, potentially causing rejection by the body. Introducing a groundbreaking alternative, Tissium presents a flexible, biocompatible polymer technology originally developed at MIT. This innovative solution adheres seamlessly to surrounding tissues, facilitating effective tissue repair after activation with blue light. Our vision is to establish this technology as the new benchmark in fixation, states Maria Pereira, co-founder of Tissium. With a background in polymers gained during her PhD studies at MIT, she emphasizes the need for less invasive alternatives to traditional surgical methods. In June, Tissium achieved a significant milestone by obtaining marketing authorization from the Food and Drug Administration (FDA) for its non-invasive, sutureless solution designed for repairing peripheral nerves. This De Novo authorization highlights the novelty of their platform and paves the way for the commercialization of their first product, following promising studies that showed patients regaining full movement of injured fingers or toes without pain. Tissium’s versatile polymers are compatible with various tissue types, including nerves, cardiovascular structures, and abdominal walls. The company is excited about exploring applications across multiple medical fields. This approval marks just the beginning, adds Christophe Bancel, CEO of Tissium. It was a challenging yet crucial step. We are now tasked with demonstrating the technology’s efficacy across various applications to benefit more patients. Before founding Tissium, Jeff Karp was a postdoctoral researcher in Robert Langer’s lab at MIT, where he focused on developing biodegradable and photocurable elastic materials for clinical applications. Following his graduation, Karp became affiliated with the Harvard-MIT Program in Health Sciences and Technology and serves as a faculty member at Harvard Medical School. In 2008, Pereira joined Karp’s lab as a visiting PhD student through the MIT Portugal Program, working on optimizing polymer properties to enhance adhesion to moist tissues. Maria transformed this polymer technology into a fixation platform applicable in various medical fields, Karp recalls. We identified a critical issue concerning congenital heart defects that required innovative solutions, which led to our initial research direction under Maria’s leadership. Pereira and her team successfully demonstrated the use of biopolymers to seal heart defects in animal models without complications. Bancel became acquainted with the technology during discussions with Karp, Pereira, and Langer in 2012, leading him to engage with numerous surgeons about their challenges. Conversations with around 15 surgeons revealed the potential impact of this technology on their practices, Bancel shares. Their enthusiasm confirmed the need for solutions that could address significant surgical challenges. Collaborating with MIT’s Technology Licensing Office, Bancel worked to commercialize the biopolymer technology while securing patents for Karp’s pioneering work. Pereira relocated to Paris after completing her PhD, officially founding Tissium in 2013 alongside Bancel, Karp, Langer, and others. The ecosystems at MIT and Harvard have been fundamental to our success, Pereira remarks. From day one, our mission has been to tackle meaningful problems for patients rather than conducting research without purpose. Our initial focus was on cardiovascular issues, but we soon realized our ambition was to establish new standards in tissue repair and fixation. After acquiring the technology, Tissium had to ensure its commercial viability. They partnered with polymer synthesis experts and developed a method for 3D printing casings for polymer-wrapped nerves. We recognized that our product combines both the polymer and necessary accessories, Bancel explains. Understanding how surgeons utilize our product was key to designing the right tools for various procedures. The demand for such innovative systems is evident. A recent analysis indicated that only 54 percent of patients achieve significant recovery post-surgery when sutures are used. Tissium’s flexible polymer approach offers a non-traumatic alternative for nerve reconnection. In a recent trial involving 12 patients, all participants reported full mobility of their injured fingers or toes without experiencing pain after one year. Current treatment options are often inadequate, Pereira notes. Sutures can introduce trauma and misalignment, affecting patient outcomes related to sensation and motor function, ultimately impacting quality of life. Tissium currently has six products under development, including ongoing clinical trials related to hernias and upcoming studies in cardiovascular applications. We had an early intuition that success in one area would likely translate to others, Bancel states confidently. Our 3D-printed production process not only facilitates tissue fixation but also enables the creation of various implantable medical devices from our polymer platform, Karp adds. The programmability of our polymers allows us to tailor degradation rates and mechanical properties, opening doors to exciting advancements in medical device capabilities. Tissium encourages professionals in the medical field to explore how their platform can enhance existing standards of care. They recognize that achieving FDA approval is a significant milestone worth celebrating. Transforming research into effective treatments that can enhance patient care is an extraordinary accomplishment, Karp expresses. It’s incredibly fulfilling to celebrate this achievement alongside all our collaborators who contributed along this journey. Langer concludes, Seeing our research from MIT reach FDA approval and positively impact lives is immensely gratifying.